The realm of time-sensitive networking (TSN) has transitioned from being confined to academic journals to becoming a practical reality in recent years. To harness the benefits of this remarkable technology, companies must comprehend the requirements of industry players and embark on the development of TSN-enabled systems. Even before establishing the IEEE TSN task group, Moxa has actively collaborated with industry partners to drive digitalization in the manufacturing sector, also known as Industry 4.0, and has been instrumental in advancing key technologies for industrial automation. Moxa recognizes the vital role of TSN as a catalyst for industrial digitization. It has made significant contributions in partnership with various industry stakeholders to construct TSN-enabled systems and leverage the proven advantages of TSN on the factory floor. In the realm of industrial automation, transmitting, receiving, and processing substantial volumes of data promptly has always presented significant challenges due to diverse equipment, interfaces, and protocols. TSN overcomes these hurdles by facilitating time synchronization on the network, allowing all connected devices to share a common time reference. Consequently, data becomes available at precise moments for specific tasks. These TSN-enabled systems boast exceptional reliability, thanks to their built-in bounded low latency, operating within a deterministic networking environment that optimizes performance and security.

Technical Breakthroughs

From a technological perspective, Moxa has engaged in partnerships to validate the reliability of the key TSN redundancy protocol, 802.1 CB, in collaboration with NXP. Furthermore, Moxa's cooperation with Intel and Keysight has demonstrated the feasibility of wireless TSN networks, which hold promise for the future.

Proven Network Redundancy

To achieve a high level of reliability, Moxa has employed the IEEE 802.1CB Frame Replication and Elimination for Reliability (FRER) protocol. This protocol sends duplicate copies of each frame over multiple disjoint paths, ensuring seamless communication even in the event of partial network failure. During Taipei Automation 2022, Moxa collaborated with NXP Semiconductors and Port Industrial Automation GmbH to test the reliability of an 802.1 CB-based ring topology, leveraging Moxa switches to connect NXP equipment. The test involved unplugging certain network cables to simulate network failure, and remarkably, the critical equipment's data packets remained synchronized and operational. This successful test not only validated robust network redundancy but also demonstrated the ability to recover from multiple points of failure rather than a single point.

Unleashing Wireless Possibilities

Another crucial step towards implementing TSN in industrial automation is ensuring data transmission in wireless applications. As numerous industrial equipment components are mobile, achieving true Industrial Internet of Things (IIoT) capabilities necessitates a wider range of TSN wireless applications. In Taipei Automation 2021, Moxa, Intel Corporation, and Port Industrial Automation GmbH developed a platform showcasing the industry's first ready-to-use, application-to-application TSN solution for instant data transmission. This platform, designed to be compatible with various communication protocols, provides flexibility and expandability, empowering the creation of next-generation smart manufacturing and logistics solutions, particularly in real-world use cases where mobile devices are essential. Wireless TSN unlocks the full potential of a unified and high-performance network infrastructure that enables the coexistence of diverse traffic types.

Taking the Technology to New Heights

In addition to proving the effectiveness of the technology, Moxa has implemented TSN in several real-world applications to help companies realize tangible business benefits.

Reducing Total Cost of Ownership in Wafer Manufacturing

By collaborating with ELS System Technology, a prominent Taiwanese lithography solution provider, Moxa has successfully integrated TSN into the wafer manufacturing process, resulting in significant benefits. This integration involves the incorporation of machine vision into the wafer misalignment correction system. Leveraging TSN technology, Moxa seamlessly combines a high-bandwidth video application with a reliable on-demand motion control CC-Link IE TSN. The outcome is a robust motion control system that incorporates machine vision capabilities, specifically designed for the misalignment correction process.

Moxa's TSN solution goes beyond providing support for different types of traffic with varying requirements. It also offers real-time, accurate motion control data about network traffic, utilizing the same open and standard network infrastructure. As a result, the TSN solution enhances the economic feasibility of the network and effectively reduces the total cost of ownership (TCO). The infrastructure becomes easy to maintain and scalable, bringing about long-term cost savings. In addition to its impact on wafer manufacturing, Moxa's TSN solution addresses the challenges associated with real-time video monitoring, which typically consumes significant data and bandwidth resources. With TSN's ultra-reliable and low-latency characteristics, Moxa enables the development of a converged application for recording and streaming live video over a network. This capability proves invaluable to Mitsubishi Electric, a prominent Japanese industrial conglomerate, as Moxa develops a specialized module to improve the logging of all system components during visual inspections. This module efficiently records video streams, waveforms, and related information, facilitating faster troubleshooting processes. Engineers no longer need to navigate through disparate devices or networks. Instead, they can conduct forensic investigations on an integrated TSN-based system, where critical and synchronized visual data is securely accessed, stored, and protected. Through these initiatives, Moxa effectively reduces costs, optimizes operations, and enhances productivity in wafer manufacturing and video component logging applications within the industrial sector.

How TSN Provides Benefits

TSN plays a crucial role in enabling smart factory automation by facilitating deterministic and real-time communication, allowing different equipment to seamlessly collaborate. As networks become larger and more complex, TSN implements traffic management and prioritizes system resources to ensure the timely delivery of critical data. This feature makes the network ultra-reliable and enhances its security. Moxa collaborates with system integrators, machine builders, and end users to harness the potential of TSN, resulting in improved returns on investment. Let's explore two use cases that demonstrate the capabilities of TSN and how Moxa partners with various stakeholders to achieve better outcomes.

Use Case 1: Machinery Manufacturer

In response to market demands for advanced, integrated, and highly automated machinery, machinery manufacturers aim to offer scalable machines with accelerated sensing capabilities and complex laser and machine control applications. However, achieving optimal performance requires seamless communication and integration among different components' proprietary networks. Moreover, operators face challenges in maintaining these networks, especially when machines are shipped abroad without comprehensive operator training. Moxa addresses these challenges by developing a unified TSN network that enables deterministic communication between cameras, sensors, and machine controls. Moxa's TSN-G5008 Series full Gigabit managed switch connects multiple I/Os to servo drivers and machine vision cameras. Previously, critical data transmission on the same cable was limited due to the nature of standard Ethernet. However, with the introduction of standard Ethernet TSN infrastructure, traffic management allows critical data to share networking resources, ensuring reliable data packet delivery. This switch enables machinery manufacturers to make their manufacturing networks compatible with TSN, harnessing the benefits of Industry 4.0.

Use Case 2: Mass Customization Production System

Shortening the production cycle is advantageous for businesses as it improves efficiency, reduces costs, and enhances flexibility. It enables businesses to meet changing market demands and offer mass-customized products, often with higher profit margins, such as commercial-off-the-shelf (COTS) products. To achieve such efficiency and flexibility, various systems, including production, assembly lines, and logistics, must operate on a unified network. This allows quick implementation of changes and adjustments to the production and distribution processes.

Moxa's TSN-G5004 and TSN-G5008 Series Ethernet switches can be deployed to combine existing proprietary networks into a single TSN-capable network, enhancing efficiency for mass customization. Most importantly, this enables the convergence of information technology (IT) and operational technology (OT), reducing the number of processes required for product manufacturing. By managing assets through a TSN-enabled network, manufacturers can facilitate adaptive production, mass customization, and production optimization, while ensuring effective control over the entire manufacturing process through deterministic communication. A simplified network topology benefits operators, as maintenance becomes easier and more cost-effective. Instead of managing multiple networks with different protocols and requirements, operators can now maintain a unified network, streamlining training and simplifying cabling. This contributes to lower maintenance costs, enabling operators to focus on core activities effectively.

Limitless Advantages

TSN revolutionizes industrial automation by bringing efficiency, simplified management, and cost-effectiveness. Its deterministic communication, whether through wired or wireless connections, ensures the ultra-reliability necessary for high-stakes and demanding industrial systems. TSN's requirement of a standardized and unified network for different devices enables IT and OT convergence, leading to fewer nodes, streamlined cabling, and simplified maintenance. These boundless benefits are enjoyed by a wide range of stakeholders, including machine builders, system integrators, and end-users.

Machine Builders

By leveraging TSN technology, machine builders can take advantage of a competitive network infrastructure that enables the convergence of motion buses and information on the same cable. This simplified architecture reduces the number of nodes, resulting in overall cost savings and reduced maintenance efforts. Additionally, TSN's ability to shorten the control loop cycle time enhances performance, enabling control over more devices. The Gigabit network capabilities of TSN also accommodate future application expansion.

System Integrators

The unified TSN network simplifies network and automation architecture by minimizing cabling and engineering efforts. TSN's capability to converge various proprietary networking technologies onto a single cable facilitates controlled and predictable network planning and scalability. As a result, the total cost of ownership is reduced, and maintenance efforts are saved.

End-Users

TSN's compatibility with existing networks eliminates the need for additional network gateways to connect different proprietary systems. Easy data access on TSN networks allows for optimized resource allocation and effort for end-users. Compared to other networking technologies, TSN excels in prioritizing critical packets over non-critical, high-bandwidth applications, thereby reducing system downtime. Additionally, leveraging standard Ethernet technologies equips TSN networks with the latest cybersecurity solutions, offering enhanced protection and adaptability in an ever-changing threat landscape.

Preparing for TSN Implementation

Implementing a TSN-capable application requires a comprehensive understanding of existing application requirements and network topology. This understanding is crucial for selecting the most suitable protocol and configuring the switches and end devices appropriately.

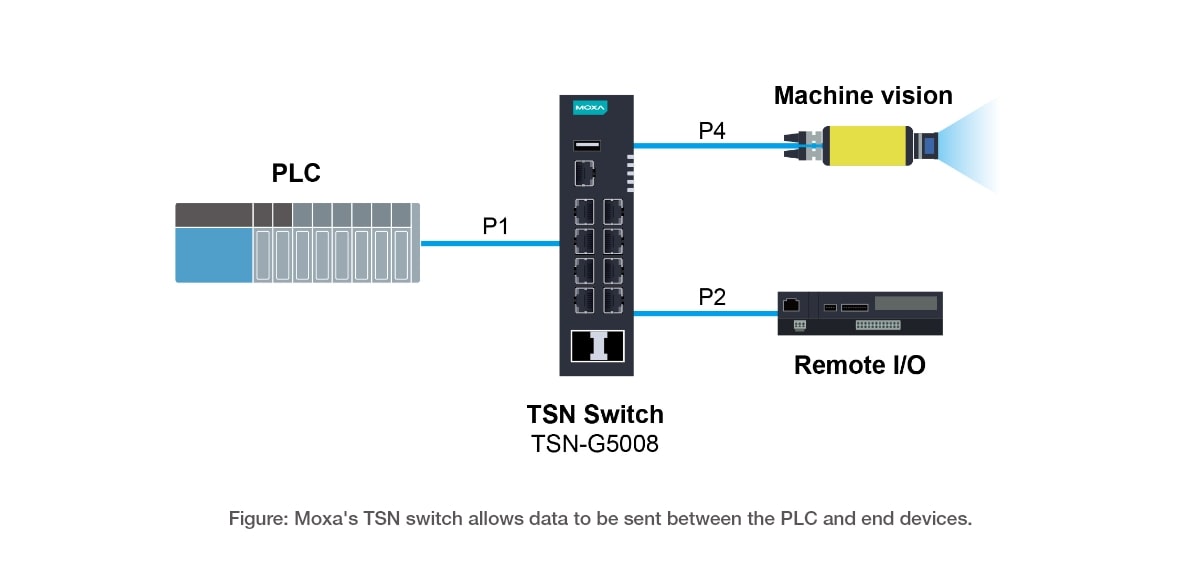

Consider an Example Requiring PLC Communications and Image Capture

Let's explore an example that involves both PLC communications and image capture, where two types of data need to be transmitted to the same host computer. In this combined network topology, the video stream is transmitted from port 4 to port 1, while the controller sends synchronization messages from port 2 to port 1, directed towards the master server. To safeguard the control packet from the high-bandwidth video stream, specific protocols must be configured on the network. This includes implementing time synchronization (802.1 AS) and time-aware shaper (802.1 Qbv) on the relevant components and ports.

The control packet follows a specific cycle, with a transmission frequency of 1 second. Within this cycle, 300 µs is allocated for cycle data, 200 µs for time synchronization data, and the remaining 500 µs is dedicated to non-cyclic data. Each slot is assigned a corresponding VLAN ID to ensure that the cycle data remains unaffected. Once the application behavior is clarified, the final step is to configure the necessary settings on the Ethernet switch and end devices.

Moxa has been diligently working to unlock the full potential of TSN technologies, enabling industry leaders to accelerate their digital transformation in industrial automation. The use cases discussed in this article demonstrate how Moxa collaborates with trusted partners and reputable stakeholders to deliver future-proof TSN solutions to clients at various stages of their digital transformation journey. Moxa's dedicated team is prepared to assist you in applications where TSN technologies can truly make a significant impact.

MOXA TSN-G5008-2GTXSFP Managed Ethernet Switch

Features

- Compact and flexible housing design to fit into confined spaces

- Web-based GUI for easy device configuration and management

- Security features based on IEC 62443

- IP40-rated metal housing

Easy World is Moxa's official distributor in the Middle East. For any further information, please contact us via sales@eworldme.com.