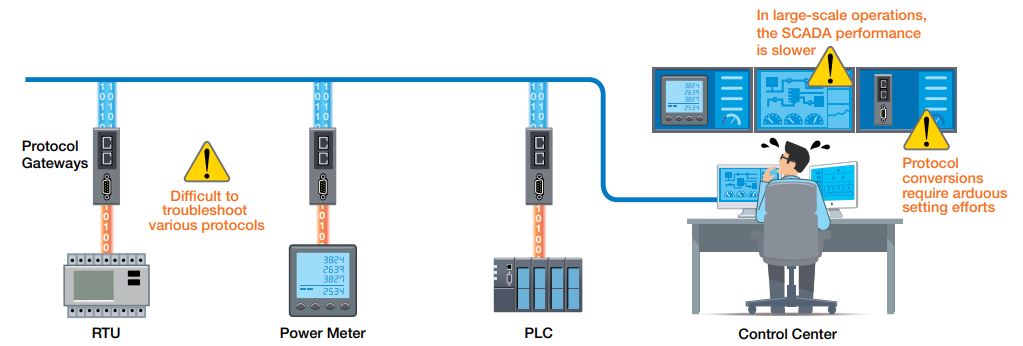

In the past, automation systems were relatively closed off

and developed a unique set of highly specialized protocols, including Modbus,

EtherNet/IP, and PROFINET. These protocols are known as industrial fieldbus protocols and provide unique benefits for different system application

purposes. Today, the push towards connected factories has also seen a growing

demand for protocol conversion due to two main reasons. First, legacy devices generally

use serial-based communication protocols, whereas modern SCADA systems, which

are becoming increasingly popular in industrial automation, rely on Ethernet

communications. To enable smooth data communication between legacy serial

devices and SCADA systems, serial-to-Ethernet protocol conversion is necessary.

Second, a factory may have several independent control systems. To enable

system-to-system communication for enhanced operational efficiency and

visibility, you need to translate data between systems. Protocol gateways play

an important role in smooth data communication in a converged communication

system. The following three criteria provide guidelines to help you choose a protocol

gateway that offers maximum benefits.

Key Question

Smooth data communication between legacy devices and modern systems relies on protocol conversion. Wouldn’t it be nice to have a protocol gateway to take care of all the complex settings and also keep data communication fast and simple?

Key Criteria 1

Efficiency Starts Here: Streamlined Configuration Made Easy

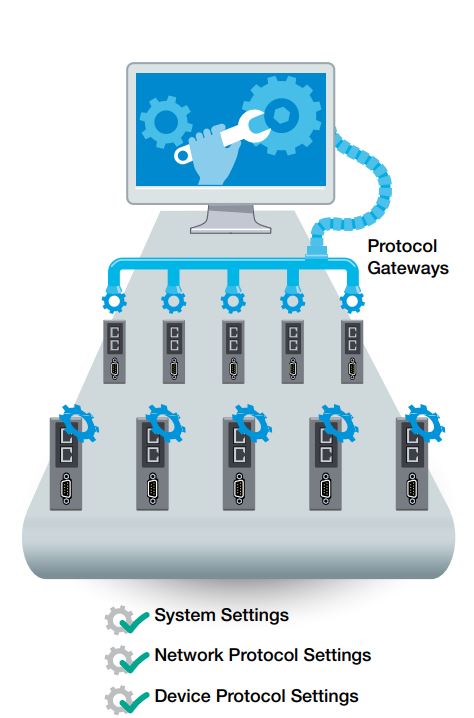

Navigating the intricacies of manual IP address and COM port

configuration for serial device servers might feel challenging, but the

complexity escalates when industrial protocol conversion settings come into

play. These settings involve a multitude of data formats, presenting an even

more intricate challenge that can overwhelm even the savviest engineers. This

is where a proficient protocol gateway proves invaluable, transcending mere

protocol conversion.

Beyond the transformation of diverse protocols, a robust protocol gateway takes on the task of simplifying the labyrinthine configurations required for both northbound and southbound protocols. To enhance this, the gateway should adeptly map which data from each protocol necessitates conversion. A user-friendly graphical interface designed for intuitive navigation becomes instrumental, significantly expediting the configuration process.

Key Criteria 2

Efficiency in Problem Solving: A Gateway to Seamless Troubleshooting

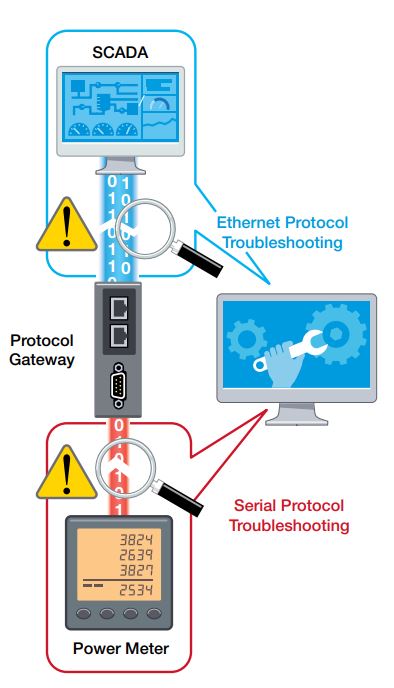

When your systems hit a snag, the toll is not just on time and productivity, it's on your bottom line. Naturally, engineers are driven to swiftly resolve issues. The path to troubleshooting isn't always smooth. The challenge magnifies when multiple devices employing diverse protocols enter the equation. Identifying the source of a communication glitch becomes an intricate puzzle, demanding the differentiation between Ethernet and serial origin points. Often, valuable time and energy are squandered on hunting down the elusive cause of communication breakdowns. Adding to the vexation is the dearth of diagnostic tools capable of rapidly pinpointing the core issue.

Resolving protocol conversion glitches necessitates a

mechanism to dissect the packets traversing the gateway. However, the realm of

troubleshooting tools and capabilities sometimes encounters limitations due to

security concerns (such as IT policy restrictions on third-party utilities) or

platform constraints (like the inability to install utility tools directly on a

PLC).

This is where a protocol gateway with an integrated utility tool or troubleshooting features proves invaluable. It empowers the swift identification of connection status, frequency of timeouts, and counts of invalid responses. When selecting your gateway solution, always keep in mind the cost and effort associated with troubleshooting, a factor that can greatly impact your operational efficiency.

Key Criteria 3

Striking the Right Balance: Optimizing Protocol Conversion for Large-Scale Applications

Navigating the terrain of protocol conversion in extensive

applications often presents a challenge of equilibrium between cost and

performance. When numerous devices across a single SCADA system necessitate

protocol conversion and seamless communication, ensuring your system's

performance aligns with your expectations becomes paramount. While opting for a

one-port protocol gateway per field device can guarantee swift data conversion

and transmission, this approach might incur substantial costs and potentially

overwhelm maintenance efforts.

On the flip side, high-port density protocol gateways offer

a cost-effective alternative, streamlining installation and management.

However, performance concerns may arise due to data handling intricacies. The

majority of protocol communications rely on poll-and-response dynamics, which,

when dealing with extensive data polls, can strain gateways and impede SCADA

system performance and response times.

The optimal solution lies in meticulously crafting your network's architecture, striking a balance between one-port and high-port density protocol gateways. High-port density gateways can be the answer, but their selection requires thorough consideration. An intuitively operable protocol gateway holds the potential to significantly enhance system operations. To make an informed choice, evaluate the three key criteria highlighted above. For instance, delve into Moxa's MGate protocol gateways, a choice that streamlines protocol conversion, ushering in swift data communication and elevating your system's efficiency.

Easy World is Moxa's official distributor in the Middle East.

For any further information, please contact us via sales@eworldme.com.