A considerable quantity of data is

produced by the Industrial Internet of Things (IIoT), which also has to

be stored. In order to meet this expanding requirement for data storage

management, more data centers are required, which raises energy

consumption. The demand to increase energy efficiency for heavy-load

equipment and devices is also noticed by factories, supermarkets,

and other high-power consumption applications. Operators of data centers and

owners of applications have to discover ways to run multiple servers and

power-hungry equipment efficiently. PDUs are used to manage and distribute

power to different equipment. Due to the growing demand for remote

monitoring, intelligent PDUs with metering and switching capabilities from

remote sites have undergone considerable market expansion in recent years. In

fact, the primary driver of PDU market development, according to a recent

industry report, is the growing demand for data center monitoring solutions. By

recording daily power consumption for payment computation and energy

management, monitoring PDUs in your application not only enables you to reduce

your energy consumption but also enables you to gather information about

the condition of your PDUs for device maintenance.

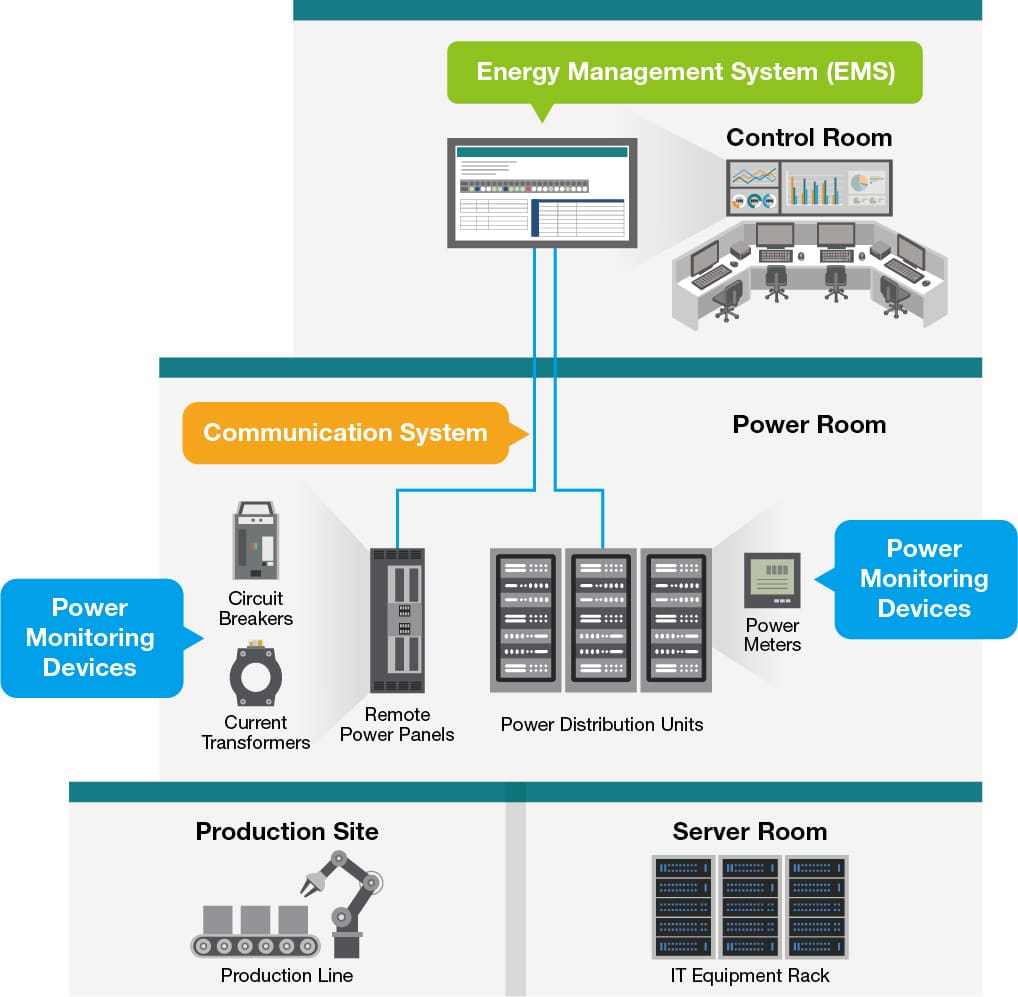

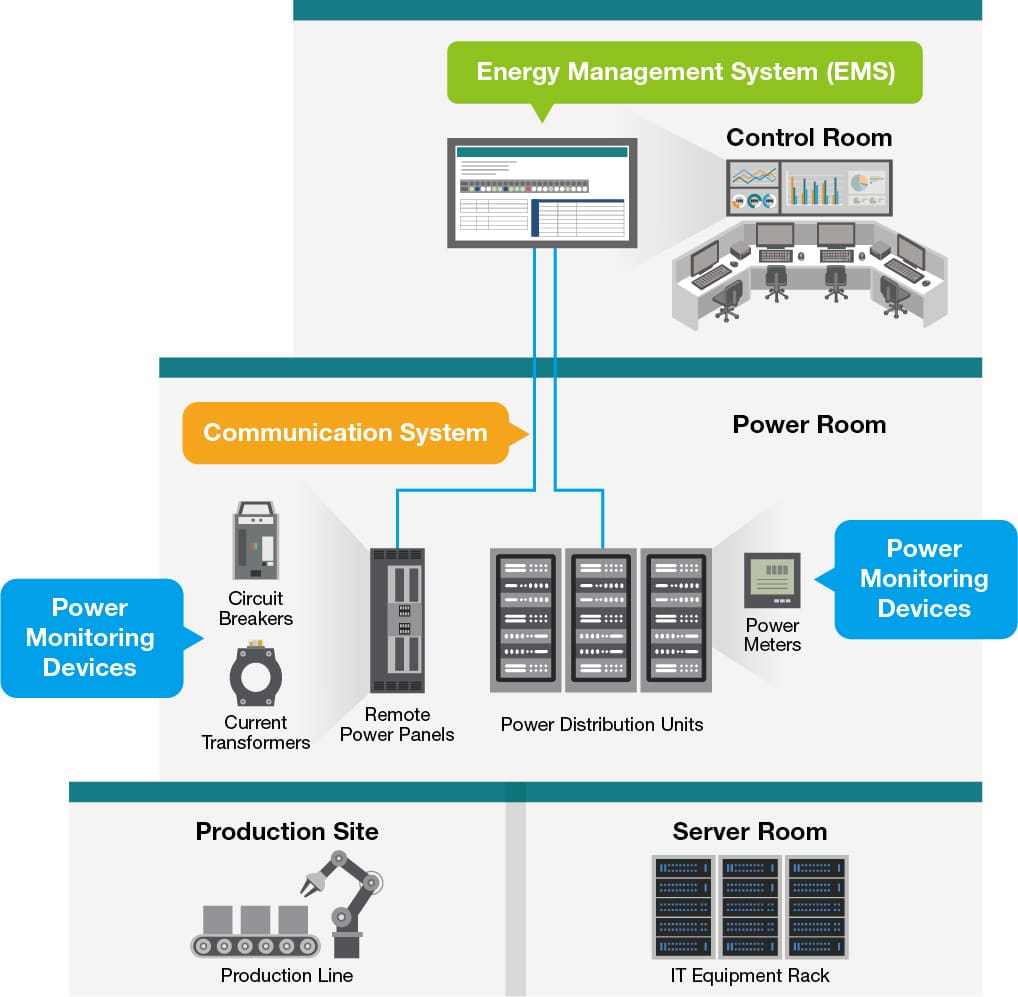

An energy management system (EMS)

requires gathering and collecting meter data from

PDUs, allowing operators to regulate, monitor, and improve the

performance of the PDUs. Additionally, remote power panels (RPPs) can be

utilized as an extension of PDUs to add extra circuits, boosting the power

distribution capacity. As a result, it's crucial to keep an eye on the circuit

breakers and current transformers to guarantee that power is balanced across

all circuits.

Smooth and efficient power

distribution requires a reliable connection between the EMS and power components

like PDUs and RPPs. Here are some tips and suggestions you may take into

account to make sure there is consistent connectivity.

Do you require new construction, or

are you in the process of retrofitting? Understand your developmental stage!

Depending on your implementation

strategy, you can enable connectivity once you've decided to monitor

the PDUs and RPPs in your application environment. Paying attention to the

following points can help you figure out the best solution before connecting

power meters, circuit breakers, and current transformers that may use different

protocols and interfaces than your EMS: - Are you planning to deploy a new PDU or retrofit an existing one?

- Does the space allow for your wiring design?

- How many PDUs are you going to connect to the network?

Depending on

your responses to these questions, you'll be able to figure out whether you

need a single-port or high-port-density connection solution. For example, a

single-port connectivity solution can be the best choice if you have limited

space for upgrading your current PDUs, and if you have enough room to install

multiple new PDUs, high port-density connectivity solutions can lead to

significant savings.

Lower Your

Installation and Maintenance Effort

A simple

networking solution can help you save a great deal of time and effort. Wiring

can be challenging when connecting lots of PDUs to a single network. As an

effective wiring solution across several PDUs and RPPs to the EMS located in

the control center, Ethernet cascading is one feature you should look for in

your connection solution. Your networking devices may periodically need backups

and upgrades even if your PDUs and RPPs are active. Device configuration and

maintenance can be made easier if your connection solutions include

user-friendly software tools.

Keep improving

operational reliability

Power

consumption calculations can be miscalculated when meter data is lost due to

unexpected network failures, which results in incorrect billing and incomplete

data for analytics. You must think about backup strategies from several angles

if you want to increase the reliability of your power monitoring system. Begin

with the networking devices. Features

like dual power inputs and high EMI immunity protect your networking

equipment from disturbance. Develop a

redundancy system for your network communications next. The market offers a

variety of network redundancy features. Check the recovery times of these

selections to see whether they are suitable for your power monitoring

application.

Easy World is Moxa's official distributor in the Middle East. For any further information, please contact us via sales@eworldme.com.