three vital system requirements

In South Africa, a highly acclaimed automotive manufacturing facility sought to enhance its production process by implementing an overhead transfer system (OTS). The OTS efficiently transports vehicles from the paint shop to the assembly location. To facilitate this process seamlessly, operators utilize a grab to send cars to the assembly section, where another operator takes control and lowers the vehicle onto the conveyor belt. The success of this transfer relies heavily on prompt command execution, leaving no room for delays.

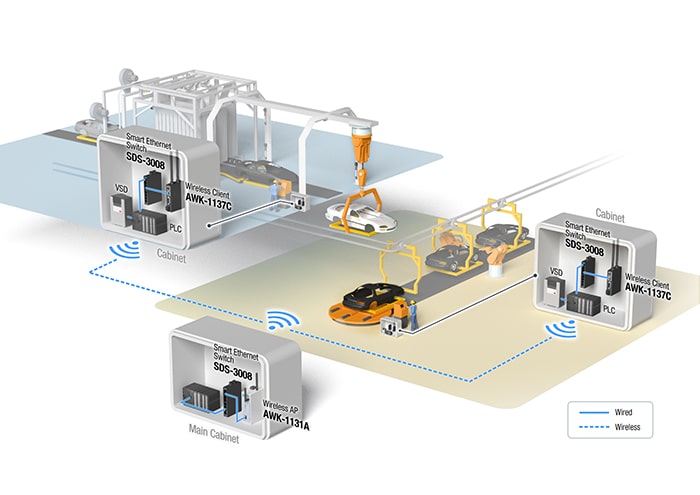

While the process may appear straightforward, a reliable network architecture is key to its smooth operation. Cabinets strategically placed throughout the site house variable-speed drives (VSDs), crucial for controlling the motor speed of the arms and the lifting mechanism of the grab. Notably, the operator's ability to operate the grab hinges on using a PLC equipped with the EtherNet/IP industrial network protocol.

Within the manufacturing site, wired communications connect equipment within individual cabinets, while communication between cabinets occurs wirelessly via Wi-Fi. This wireless communication enables operators to track the location of the cab (the vehicle frame pre-assembly) and prevent potential issues such as collisions. Consequently, the main control cabinet requires a powerful, dependable Wi-Fi connection to effectively monitor and control the cabs as they traverse the manufacturing facility.

To ensure the reliable operation of the grab, three vital system requirements must be met:

1. Reliable Network for Efficient Vehicle Transfer:

At

industrial sites, maintaining reliable data transmission between the

operator and the grab is paramount for maintaining efficiency and safety.

Moxa's SDS-3008 smart switch played a pivotal role in achieving

exceptional communication efficiency for this project. Tailor-made traffic

management functions offered by the SDS-3008 addressed the operator's

specific requirements. Unlike unmanaged switches, Moxa's SDS-3008 can

effectively manage traffic flow, mitigating broadcast problems commonly

encountered with EtherNet/IP-based PLCs in large manufacturing sites.

Additionally, Moxa's SDS-3008 is designed with OT engineers in mind,

featuring plug-and-play functionality that eliminates the need for

time-consuming configurations typically associated with managed switches.

The use of Moxa's AWK-1131A wireless AP and AWK-1137C client further

enhanced smooth and robust communications across the Wi-Fi network, thanks

to their rugged industrial designs that minimize interference common in

manufacturing sites.

2. Industrial Design and User-Friendly Network Functions for Simplified Maintenance:

To optimize

operational efficiency in the automation industry, operators can monitor the system status directly on the HMI or SCADA system. Moxa's SDS-3008

incorporates the three most commonly used IA protocols, including EIP,

enabling operators to conveniently view the network from the HMI. This

familiar system empowers operators to react promptly to network events, minimizing

system downtime effectively.

3. Compact Size and Flexible Mounting Options for Installation in Confined Spaces:

Limited space within industrial cabinets often challenges automation engineers and system integrators in manufacturing sites. Moxa's SDS-3008 and AWK-1137C address this predicament with their compact palm-sized form factor and versatile installation options, effortlessly fitting into almost any industrial cabinet. By employing Moxa's devices, automation engineers and system integrators benefit from a seamless solution that eliminates the need for workarounds, expediting deployment times.

Featured Product

Easy World's Moxa's official distributor in the Middle East. For any further information please contact us via sales@eworldme.com.