In today’s fast-paced industries, real-time data and smart connectivity are now an essential commodity rather than an option. Moxa's remote I/O solutions are an example of the shift in the industrial landscape as they provide proactive intelligence, industrial-strength reliability, and out-of-the-box deployment. Moxa has designed its remote I/O solutions to help industry accelerate insights derived from field data while ensuring a stable connection with real-time access to that data. With Moxa, organizations will transition their operations from reactive to predictive in real time.

See It In Action: Introducing Your Trusted Field Partner

In a brief video, you'll see how Moxa's remote I/Os operate in the field with you, providing you with integrated field monitoring and better decision-making capabilities in real time, wherever you need them, whenever you need them.

Why Moxa

Proactive Performance

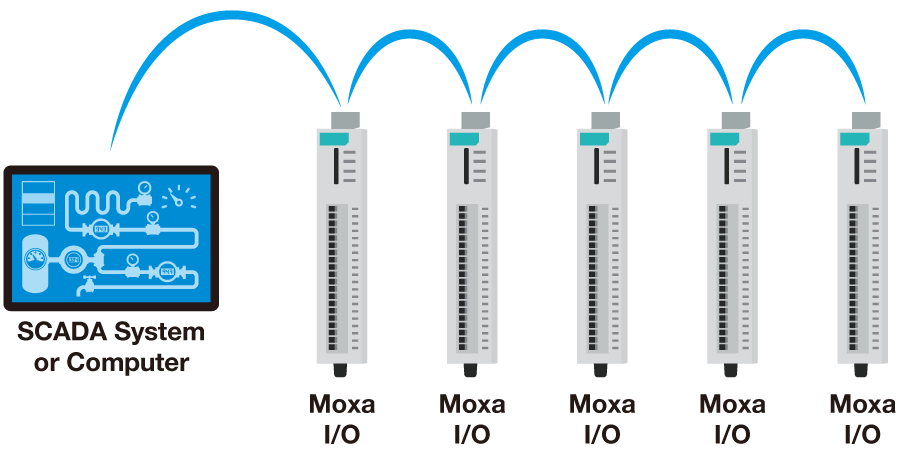

Moxa’s remote I/O devices are designed with event-driven push communication and Click&Go Plus Logic to move beyond traditional polling-based systems. This intelligent design eases the load on the host system and improves response times, contributing to the integration of IT and OT systems.

Easy to Use

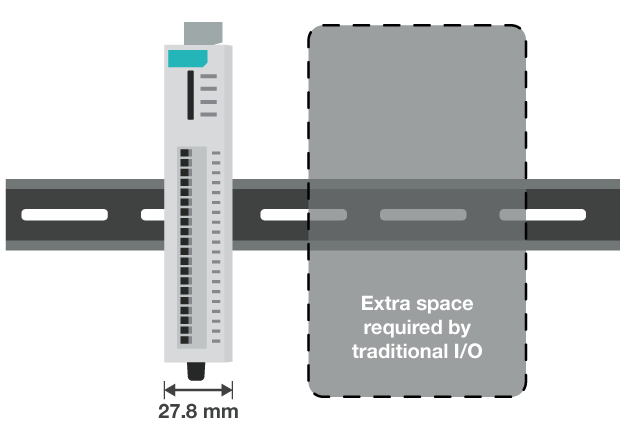

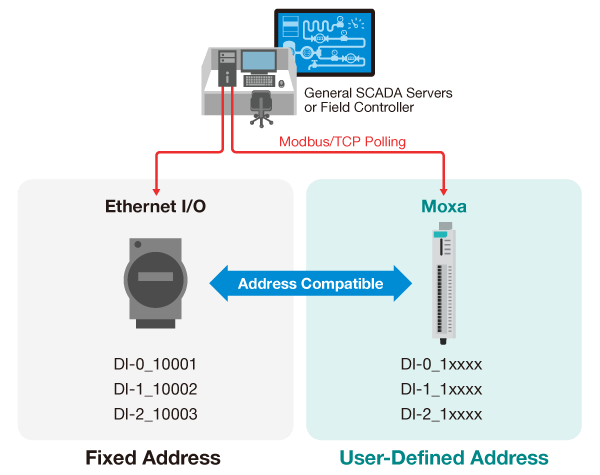

Moxa designs simplify installation by providing front-access wiring, daisy-chained Ethernet, and adaptable Modbus configurations to reduce effort and complexity in integration.

Impeccable Reliability

Moxa remote I/O devices are built for industrial robustness. Moxa remote I/O devices have a wide temperature operating range, meaning they are designed for extreme conditions, with tolerances from extreme heating to freezing. And for environments that have massive amounts of noise, they have enhanced RS-485 stability on select models like ioLogik R1200 that increases noise immunity by 137% for secure communications.

Where Remote I/Os Make an Impact

Moxa remote I/Os are providing robust, compact control of lighting, roadside, and field systems across all forms of smart transportation, from tunnels to terminals, with products designed to operate in harsh outdoor environments.

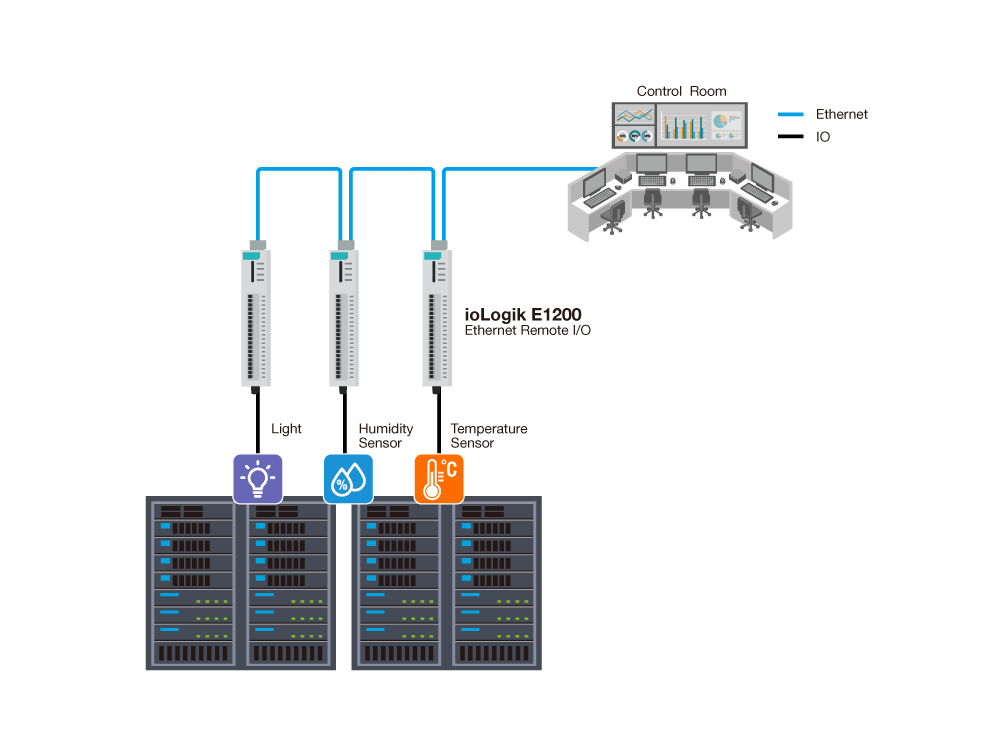

Data Center

Moxa remote I/Os are great for thermal monitoring, legacy equipment integration, and energy management, as they support Modbus and SNMP protocols to easily connect with IT systems even in limited space.

Manufacturing

In terms of real-time process monitoring and machine diagnostics, Moxa remote I/Os provide flexible I/O combinations, quick implementation, and easy connection with SCADA or MES systems to make digitalization possible.

Choose the Right Remote I/O for Your Needs

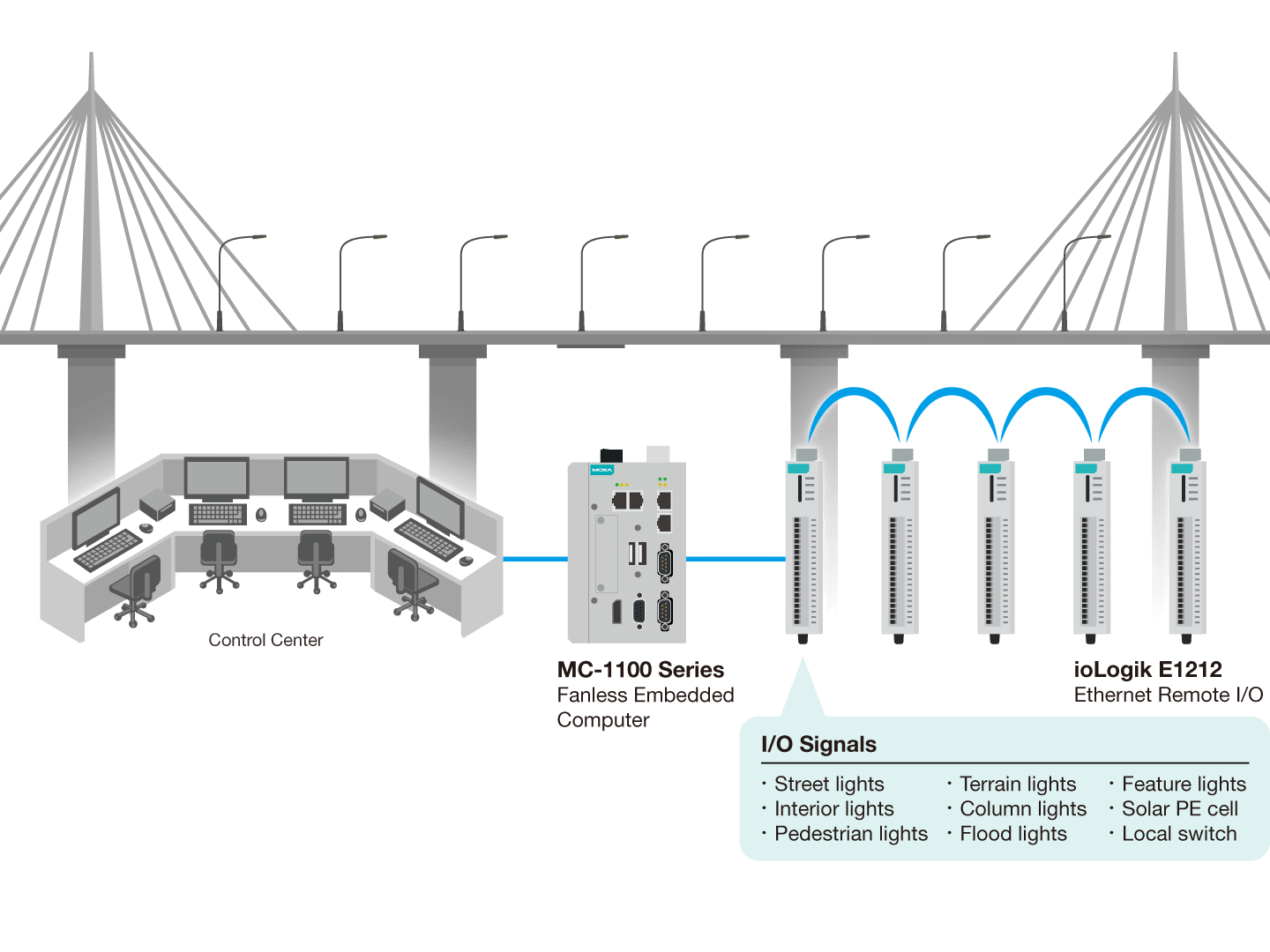

ioLogik E1200 Series

Effortless installation

Compact front-wiring design streamlines setupSmart networking

Built-in 2-port Ethernet switch for daisy-chain connectivitySeamless IT integration

Supports Modbus TCP, RESTful API, and SNMPProactive data reporting

Real-time active communication via MX-AOPC UA Suites

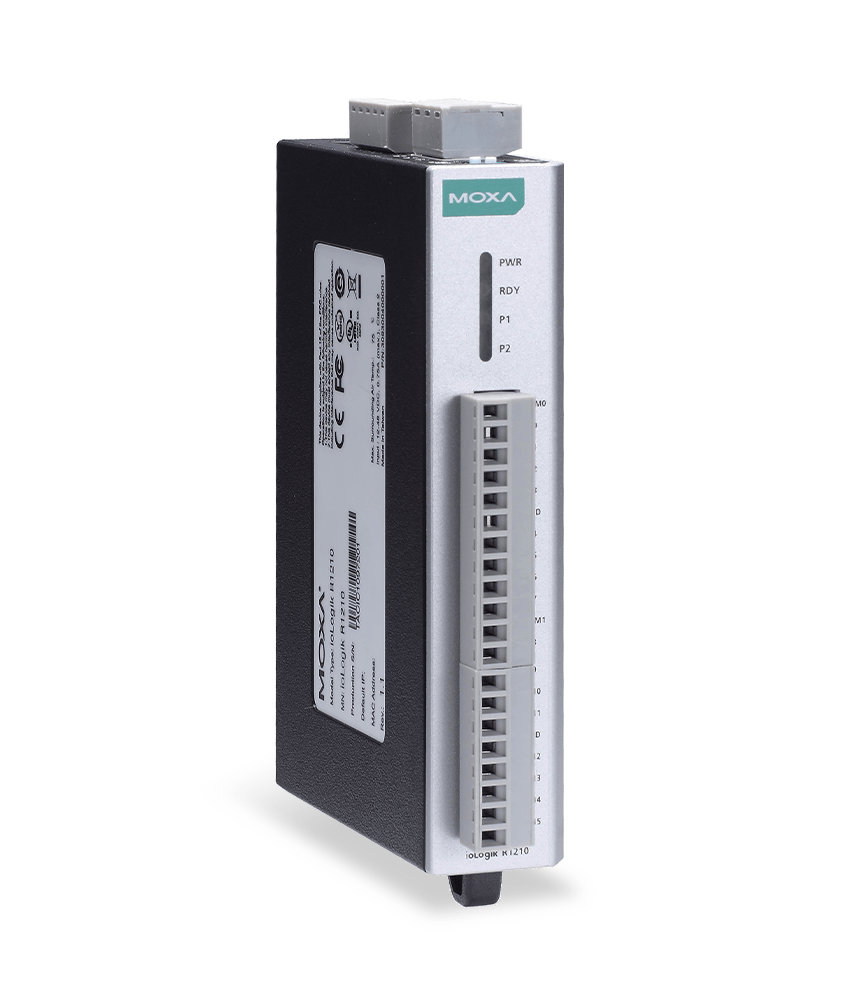

ioLogik R1200 Series

Fast and easy deployment

Compact front-wiring design for simplified installationSuperior stability

137% wider common mode voltage enhances RS-485 reliabilityReliable connectivity

Dual RS-485 or repeater mode for flexible wiring and data flow continuityHassle-free maintenance

Configure communication parameters and upgrade firmware via USB or RS-485

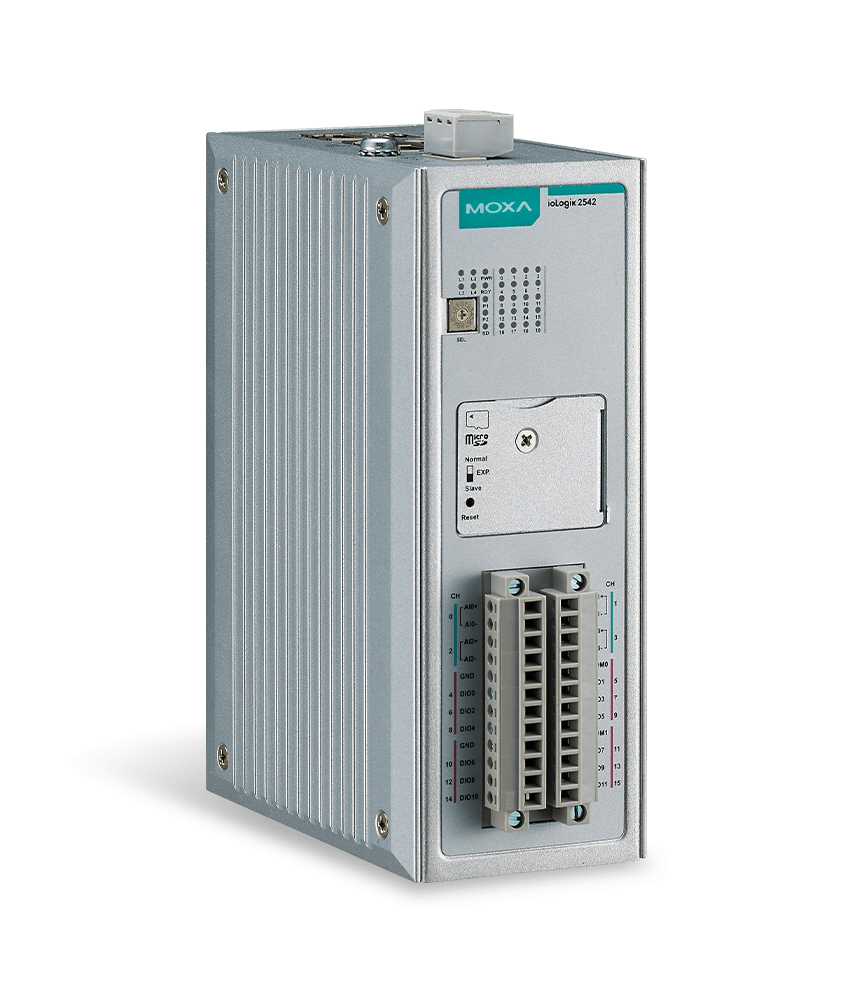

ioLogik 2500 Series

Edge Intelligence

Built-in Click&Go Plus logic enables local decision makingHighly scalable

Expandable with up to 8 additional ioLogik E1200 unitsFlexible connectivity

4-port Ethernet switch and dual serial ports for seamless integrationReliable data continuity

Auto lost data recovery via MX-AOPC UA Suites

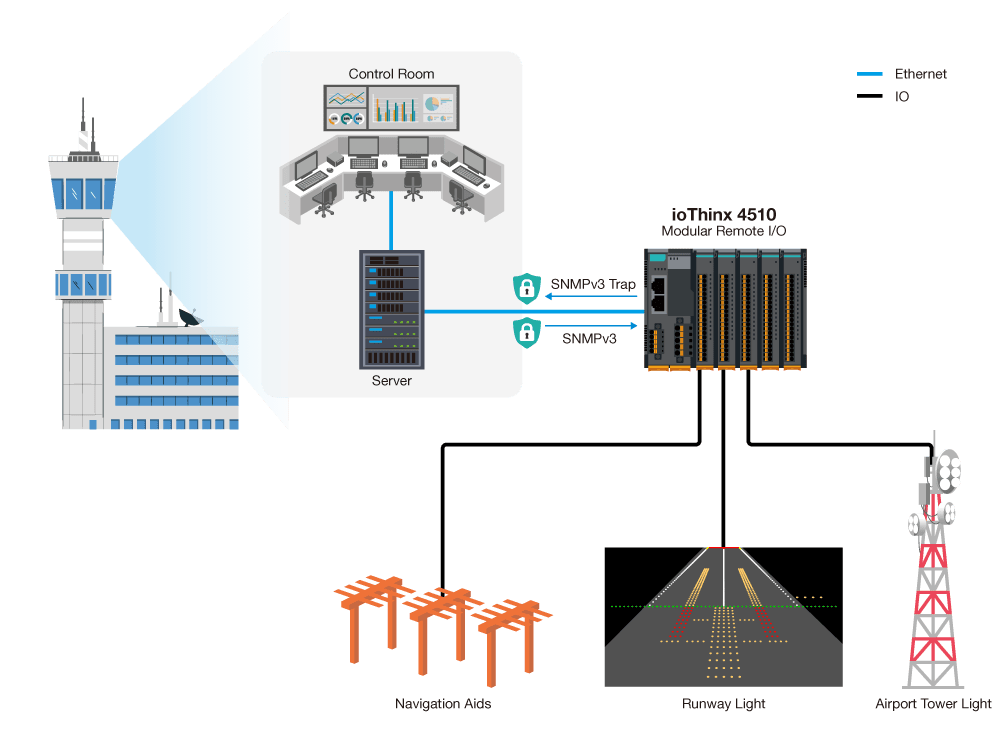

ioThinx 4510 Series

Quick installation

Tool-free setup and auto reconfiguration reduce downtimeFlexible expansion

Supports up to 32 modules for scalable applicationsMultiple connectivity options

2-port Ethernet switch and 3-in-1 serial port for various industrial setupsIT-ready design

Supports Modbus TCP, RESTful API, MQTT, and SNMPv3 for modern IIoT integration

Where Remote I/Os Make a Difference

Intelligent Transportation

From bridges to airports, Moxa’s remote I/Os provide dependable control of outdoor systems such as lighting, roadside cabinets, and field devices—featuring a compact, rugged design engineered for harsh environments.

Data Center

Whether it's temperature monitoring, integrating power meters, or upgrading legacy systems, Moxa remote I/Os provide flexible, space-efficient solutions that seamlessly connect to IT systems through Modbus or SNMP.

Manufacturing

From factory emissions to machine status signals, Moxa remote I/Os enable digital transformation with simple installation, versatile I/O support, and seamless integration with MES or SCADA platforms.

Selection Guide

| Remote I/Os |

|---|

| I/O |

| Front-end logic |

| Ethernet port |

| Serial |

| Northbound protocol |

| Active protocol |

| Southbound protocol |

| Operating Temp. range |

| Standards and Certifications |

ioLogik E1200 Series

|

ioLogik R1200 Series

|

ioLogik 2500 Series

|

ioThinx 4510 Series

|

|---|---|---|---|

| DI, DO, Relay, AI, AO, RTD, TC | DI, DO, Relay, AI, AO | DI, DO, AI (Relay, AO, RTD, TC expandable) | DI, DO, Relay, AI, AO, RTD, TC expandable by 45MR Series |

| - | - | Click&Go Plus | - |

| 2 | - | 4 | 2 |

| - | 2 x RS-485 | 2 x RS-232/422/485 | 1 x RS-232/422 or 2 x RS-485 |

| Modbus TCP server (slave) EtherNet/IP adapter SNMPv1/v2c RESTful API | Modbus RTU Server (Slave) | Modbus TCP server (slave) SNMPv1/v2c/v3 RESTful API | Modbus TCP server (slave) SNMPv1/v2c/v3 RESTful API via TLS |

| Moxa AOPC (Active tag) SNMPv1 Trap | - | Moxa AOPC (Active tag) SNMPv1/v2c Trap CGI command | MQTT via TLS SNMPv1/v2c/v3 Trap SNMPv2c/v3 Inform |

| - | - | Modbus TCP client (master) Modbus RTU client (master) | Modbus RTU client |

| Standard models: -10 to 60°C (14 to 140°F) Wide temp. models: -40 to 75°C (-40 to 167°F) | Standard models: -10 to 75°C (14 to 167°F) Wide temp. models: -40 to 85°C (-40 to 185°F) | Standard models: -10 to 60°C (14 to 140°F) Wide temp. models: -40 to 75°C (-40 to 167°F) | Standard models: -20 to 60°C (-4 to 140°F) Wide temp. models: -40 to 75°C (-40 to 167°F) |

| CID2, ATEX Zone 2, CE, FCC, UL | CE, FCC, UL | CID2, ATEX Zone 2, CE, FCC, UL | CID2, ATEX Zone 2, CE, FCC, UL |